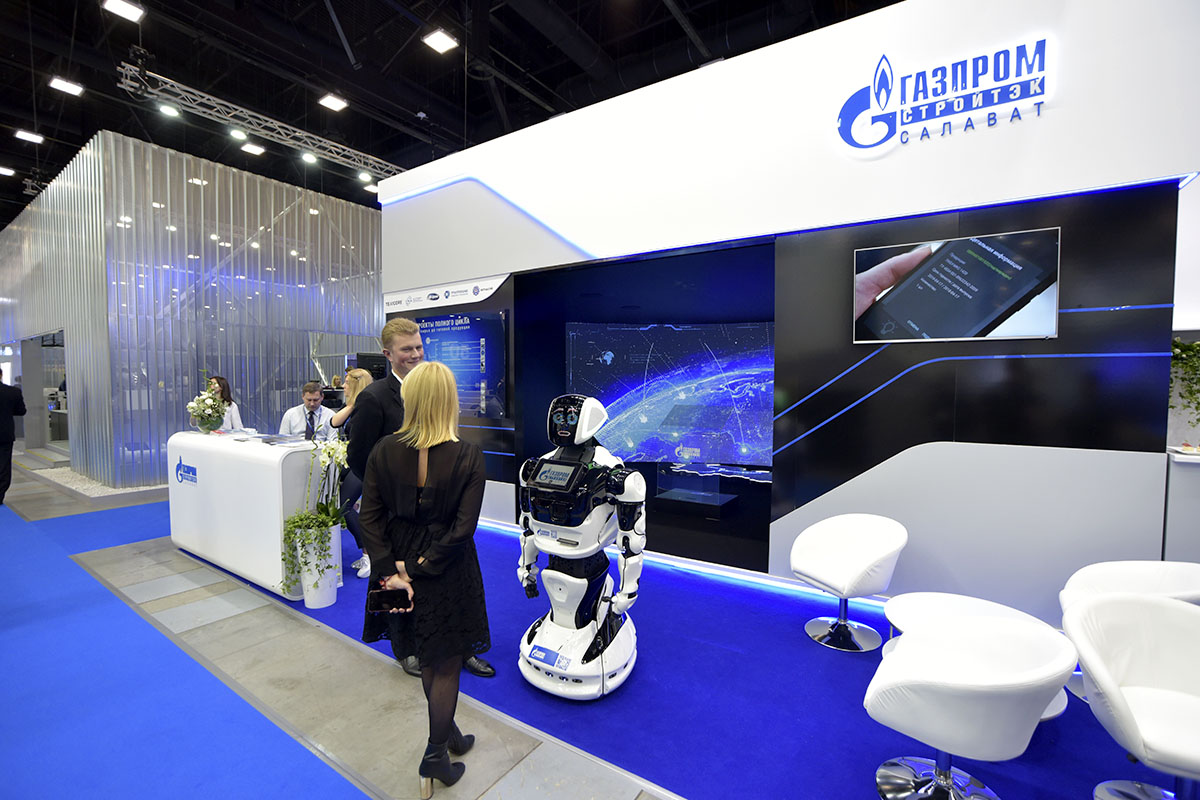

Gazprom StroyTEK Salavat presents innovative import-substituting products at the exhibition

As part of Gazprom’s 308 Department’s corporate exposition Modern technologies in the gas industry that opened in Pavilion G, Gazprom StroyTEK Salavat showed prototypes of innovative bio- and EURO plugs, a pipe with a concrete weight coating, powder anticorrosive coating CoatMet AFM, reinforced thermoplastic tape and protective fiberglass coating for pipes. At its main exposition in Pavilion F, the company showed on a large screen 3D models of its solutions.

"The main trend of this year for Gazprom StroyTEK Salavat was a strategy aimed at coming up with innovative products to meet the key challenges facing the industry at the current moment," – pointed out Alexander Ksenitov, Head of the Innovation and R&D Department of the company.

As one of the most engineering advances of the company, the expert mentioned the protective fiberglass coating Kolchuga that comes in two versions: standard and reinforced. It protects the anticorrosion coating of pipes from mechanical damage used both in the cut-and-cover (trench) method of pipe laying and in the trenchless one. To manufacture the coating, a partner METAKLEY JSC, the company's partner, created an advanced reinforced thermoplastic tape manufacturing technology.

"We are currently working hard to solve the problem of construction and reconstruction of gas pipelines located in the protected zones. In order to revamp a gas pipeline located in a security zone or near residential buildings, it is necessary to draw up special technical conditions, including a wide range of remedial measures, which must be agreed upon by the Ministry of Construction of the Russian Federation and other supervisory agencies. At the moment, work is underway to create a product that will solve this problem", – Alexander Ksenitov made clear.

One more innovative anticorrosive means of pipe protection, which has proved its effectiveness, is the powder coating CoatMet AFM. It is applied using gas-flame plating method and can be used on structures with complex geometry both in the factory and in close proximity to Gazprom facilities. According to its performance figures, CoatMet AFM coating is on a par with, and in some respects is better than thermoset-based solutions (using polyurethanes, epoxy and like materials).

Much consideration is being currently given to the construction ecology; and at the pipe transportation and storage facilities, BIO plugs manufactured by METAKLAY are already being extensively used. They are based on a composition of recycled high density polyethylene and nano-additives. Under the ultraviolet light, the plug turns into powder because it has organic additives, after which microorganisms destroy it in the ground. The use of such plugs at the facilities of Gazprom will reduce negative impact on the environment. EURO plugs is a new product of the company, designed for pipes with a diameter of 520 to 1420 mm made to order for TMK. During the construction of the TurkStream gas pipeline, it was delivered to the Serbia-Bulgaria section.

Calendar

Calendar

Online application

Online application

Map

Map

How to get

How to get